SUBHEAD: Will we be able to use industrial capacity to make those things we will need in the future?

Image above: A wire brush, for scraping rust off metal, made made by Vasilii Arkhipov, in 1992, after the collapse of the USSR. From "Home Made: Contemporary Russian Folk Artifacts" by Vladimir Arkipov (www.folkforms.ru) .

Dmitry Orlov on 24 February 2010 in Club Orlov -

Image above: A wire brush, for scraping rust off metal, made made by Vasilii Arkhipov, in 1992, after the collapse of the USSR. From "Home Made: Contemporary Russian Folk Artifacts" by Vladimir Arkipov (www.folkforms.ru) .

Dmitry Orlov on 24 February 2010 in Club Orlov -

(

http://cluborlov.blogspot.com/2010/02/industrys-parting-gifts.html)

We are going to need some widgets made. They do not have to be as sophisticated or as complicated as the widgets we have today. For instance, once it is no longer possible to launch satellites, we will no longer have satellite navigation systems such as the Pentagon-run GPS or the joint Russian/Indian GLONASS. To compensate, we will have to go back to using radio beacons, so that boats can find harbor entrances in the fog. Another example: once laser printer and ink-jet technology no longer exists, we will need to bring back the humble old teletype. Add to that all of the other humble adaptations that will be needed once the electric grid and municipal services first become unaffordable, then cease to exist.

Countless items will have to be manufactured, one way or another, using local means, because imports are also going to first become unaffordable, then cease to exist. These items will have to be far more robust, longer-lasting and maintainable than the consumer products of today. A population reduced to a permanent state of camping out shares certain characteristics with astronauts and deep-sea divers and others who live and work on the edge: their reliance on their equipment is absolute. In such situations, an unreliable or unmaintainable product is worse than no product at all, because it gives a false sense of security. Making such high-quality items is by no means technically impossible; things can be made so well that they will last a lifetime and even become heirlooms. This, then, should be the new main thrust of industrial activity: to manufacture and distribute products with the understanding that this process will run out of resources and stop. These products must be designed to outlive the process by which they are made, by as long as possible.

How would one organize such a production scheme on an industrial scale? Is it even possible? If it is not, then the only recourse is to have this done by garage, basement and backyard tinkerers, using plans shared over the internet. In fact, this seems to be what is happening, and it very well may be all that ever happens. If that is the case, then production volumes will be much lower than what can be attained with mass production techniques, leaving a huge unmet demand, and a far more precipitous drop in living standards than is really necessary. But let us imagine for a moment that we can do better. How would we go about organizing such an effort? Here are some thought experiments—projections, if you will—based on what I've observed over the years. I present three scenarios—not a complete list, I hope, but these are all the scenarios I can think of without straining my imagination. I hope that you can do better.

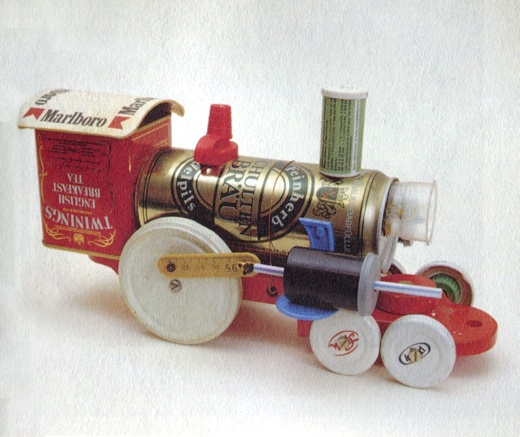

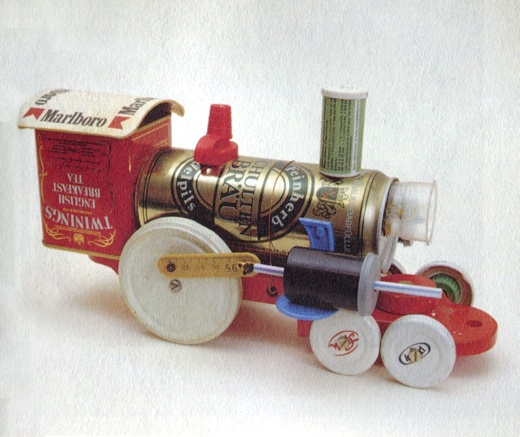

Image above: From "Home Made" a toy train by Aleksandr Chebotaryov for his son in 1996.

Company A

Image above: From "Home Made" a toy train by Aleksandr Chebotaryov for his son in 1996.

Company A

Suppose you have a company that sets out to make a widget. Let's call it Company A. Its founders are all engineers, of an uncompromising sort, and the widget they design and manufacture is of tremendous longevity, durability and overall quality. Taking full advantage of economies of scale, they design a single, universal model that uses the maximum possible number of interchangeable, off-the-shelf commodity components, optimize it for mass production, and stockpile a gigantic inventory, including all the custom spare parts that they feel would ever be needed. To make sure that their product is sufficiently idiot-proof, they even test it on selected members of their own families. The engineers concentrate on what they feel is important, neglecting questions of marketability and competitive pricing, and the result is that Company A's widget cost double of functionally comparable widgets sold by the competition.

When consumers refuse to pay so much more than they feel they have to, Company A's widget fails in the marketplace, and the company is liquidated. Its remaining stock of widgets is eventually sold at a large discount, while Company A's investors get almost nothing. Those who are lucky and clever enough to buy one of these widgets go on to use them for the rest of their lives, never needing to buy another one, because, being grossly overdesigned and overbuilt, they simply never fail or wear out. In spite of Company A's failure as a business, the reputations of the engineers do not suffer at all, because, after all, their product is a tremendous technical success. Furthermore, since the installed base of their widgets never goes down, the engineers remain in demand as consultants, called in whenever issues do arise. Some of them form a small company that maintains an inventory of spare parts, and uses it to recondition and service their widgets far into the future. Eventually, long after the names of Company A's competitors are all forgotten, its name enters the language as the generic term for the widget it once made.

Company B

Now suppose you have another company, Company B, which makes a similar sort of widget. Its founders are all MBAs who are mainly interested in things like growth strategies, market penetration and continuous profitability. They are superficially interested in the widget itself, as consumers or from a sales and marketing perspective. The internal workings of the widget are, to them, best left up to the engineers. They do hire some smart engineers to start with, but don't give them much of a voice in making strategic decisions, and manage them by doling out bonuses and promotions for things like new features, shorter time to market, and lower production costs. They see to it that the widget they make is competitively priced, fashionably designed, and quickly obsolescent, so that consumers are ready to pay again and again just to get the latest features and designs. Durability and longevity are not a concern, since one or two years of semi-reliable service is all that's needed for Company B to come up with a new, improved version that consumers can be persuaded to buy given a sufficiently generous trade-in offer.

They work to boost revenue by offering an extended warranty or a service plan (made necessary by frequent breakdowns), charging for premium customer service (made necessary by their normal customer service, which consists of a robotic phone maze backed by a few trainees in India who just read aloud from Company B's public web site in a listless, stuttering monotone) and offering numerous enhancements and upgrades (made necessary by annoyances or missing functions within the base product). They also build a profit center out of selling spare parts. They see to it that their product does not contain any commodity parts, and that no parts are interchangeable between model years, so that every replacement part has to be purchased through a dealer. Company B does quite well, becoming profitable, doubling in size several times, and gains a commanding market share.

But then the troubles begin. First, given the short replacement cycle of its widget, it becomes harder and harder for Company B to contain costs while continuing to increase production. Costs of key inputs, such as certain metals, plastics, energy to run the plants, and shipping and distribution costs, all start going up, making their widgets more expensive to produce. At the same time, it becomes increasingly difficult to pass these higher costs on to the consumers. Concerted efforts at cost containment, championed by senior management, burn up more money than they find in savings. Second, turnover among the engineering staff starts to creep up, and after a while employee retention becomes a major problem. An effort is made to boost recruitment, but paradoxically this only increases the turnover rate, until the average tenure of an engineer is shorter than the time it takes to learn the product.

As development timelines slip and defect rates increase, management throws money at the problem by hiring high-priced consultants and engineering methodology snake oil salesmen, all to no avail. Lastly, although Company B manages to hold on to its market share, the overall size of the market starts to shrink as consumers run out of money and curtail their purchases, holding on to their outdated widgets until they fail, then learning to live without them. Eventually Company B is acquired by a foreign company, which crates up and ships off the few pieces of the operation it finds useful and auctions off the rest. As Company B's customers try to eke out a bit more life out of their half-broken widgets, the average resale price of Company A's widget soars well above its initial list price, and its proud owners go around looking insufferably smug.

Company C

Company C is not really a company but a consortium organized by a group of activists who correctly perceive the great need for this widget and decide to tackle the issue head-on through tireless community organizing. Their initial concept includes plans for the widget to carry a "100% Sustainable" label. A group of retired community college professors takes several months to define the technology selection criteria that would allow the project to meet the 100% sustainability requirement. In the end, they decide that the widget could be made out of hand-worked clay baked in a solar oven, but only if the oven itself is exempted from the 100% sustainability requirement. It could also be hand-woven out of wicker and bamboo, provided that these were subsequently composted and the compost returned to the soil where the wicker and bamboo were grown. However, the widget can't be made to work without the use of Nylon, Vinyl, Neoprene, epoxies and other fossil fuel-based synthetics, nor can it operate without components made with mined, increasingly scarce elements such as tantalum, gallium and lithium.

The organizers then move to drop the "100% sustainable" requirement and to shift their focus to "Serving community at every level." Production of the widget is to include hands-on job training programs at community colleges and vocational training centers, assembly tasks would be done by groups of mentally and/or physically challenged individuals, while testing, kitting-out and packing would be performed by religious groups (in conservative states) and groups of people with alternative sexual orientations (in liberal ones). From the outset, the consortium is plagued by scandal. The "Made with Pride in the USA" decals turn out to be made in China. The Visual Installation Guide is never printed in Braille. Worst of all, due to communication difficulties caused by static and noise on the line during conference calls, the lesbians (who were to lovingly pack completed widgets in wicker baskets hand-woven by Haitian orphans and filled with organically grown straw) turn out to be not lesbians at all, but eager out-of-work Thespians (of both genders, and barely half of them gay) and Fezbians (perfectly conventional males with convincing falsettos united by their predilection for wearing a fez). The consortium collapses in acrimony and mutual recriminations without shipping a single completed widget. Out of sheer frustration, one of the organizers, laboring alone, succeeds in assembling a single working widget, and donates it to the Smithsonian.

Conclusion

Based on the foregoing, it would appear that the choice is between failing at something and failing at everything. Company A makes excellent widgets but fails to pay back its investors. Company B makes money but its widgets quickly become useless trash. Company C entertains us with its feckless shenanigans but fails to produce any widgets. I really do hope that I am missing something. Is there a Company D out there? If so, please tell me, because I would really like to know.

.

Image above: A wire brush, for scraping rust off metal, made made by Vasilii Arkhipov, in 1992, after the collapse of the USSR. From "Home Made: Contemporary Russian Folk Artifacts" by Vladimir Arkipov (www.folkforms.ru) .

Dmitry Orlov on 24 February 2010 in Club Orlov -

(http://cluborlov.blogspot.com/2010/02/industrys-parting-gifts.html)

We are going to need some widgets made. They do not have to be as sophisticated or as complicated as the widgets we have today. For instance, once it is no longer possible to launch satellites, we will no longer have satellite navigation systems such as the Pentagon-run GPS or the joint Russian/Indian GLONASS. To compensate, we will have to go back to using radio beacons, so that boats can find harbor entrances in the fog. Another example: once laser printer and ink-jet technology no longer exists, we will need to bring back the humble old teletype. Add to that all of the other humble adaptations that will be needed once the electric grid and municipal services first become unaffordable, then cease to exist.

Countless items will have to be manufactured, one way or another, using local means, because imports are also going to first become unaffordable, then cease to exist. These items will have to be far more robust, longer-lasting and maintainable than the consumer products of today. A population reduced to a permanent state of camping out shares certain characteristics with astronauts and deep-sea divers and others who live and work on the edge: their reliance on their equipment is absolute. In such situations, an unreliable or unmaintainable product is worse than no product at all, because it gives a false sense of security. Making such high-quality items is by no means technically impossible; things can be made so well that they will last a lifetime and even become heirlooms. This, then, should be the new main thrust of industrial activity: to manufacture and distribute products with the understanding that this process will run out of resources and stop. These products must be designed to outlive the process by which they are made, by as long as possible.

How would one organize such a production scheme on an industrial scale? Is it even possible? If it is not, then the only recourse is to have this done by garage, basement and backyard tinkerers, using plans shared over the internet. In fact, this seems to be what is happening, and it very well may be all that ever happens. If that is the case, then production volumes will be much lower than what can be attained with mass production techniques, leaving a huge unmet demand, and a far more precipitous drop in living standards than is really necessary. But let us imagine for a moment that we can do better. How would we go about organizing such an effort? Here are some thought experiments—projections, if you will—based on what I've observed over the years. I present three scenarios—not a complete list, I hope, but these are all the scenarios I can think of without straining my imagination. I hope that you can do better.

Image above: A wire brush, for scraping rust off metal, made made by Vasilii Arkhipov, in 1992, after the collapse of the USSR. From "Home Made: Contemporary Russian Folk Artifacts" by Vladimir Arkipov (www.folkforms.ru) .

Dmitry Orlov on 24 February 2010 in Club Orlov -

(http://cluborlov.blogspot.com/2010/02/industrys-parting-gifts.html)

We are going to need some widgets made. They do not have to be as sophisticated or as complicated as the widgets we have today. For instance, once it is no longer possible to launch satellites, we will no longer have satellite navigation systems such as the Pentagon-run GPS or the joint Russian/Indian GLONASS. To compensate, we will have to go back to using radio beacons, so that boats can find harbor entrances in the fog. Another example: once laser printer and ink-jet technology no longer exists, we will need to bring back the humble old teletype. Add to that all of the other humble adaptations that will be needed once the electric grid and municipal services first become unaffordable, then cease to exist.

Countless items will have to be manufactured, one way or another, using local means, because imports are also going to first become unaffordable, then cease to exist. These items will have to be far more robust, longer-lasting and maintainable than the consumer products of today. A population reduced to a permanent state of camping out shares certain characteristics with astronauts and deep-sea divers and others who live and work on the edge: their reliance on their equipment is absolute. In such situations, an unreliable or unmaintainable product is worse than no product at all, because it gives a false sense of security. Making such high-quality items is by no means technically impossible; things can be made so well that they will last a lifetime and even become heirlooms. This, then, should be the new main thrust of industrial activity: to manufacture and distribute products with the understanding that this process will run out of resources and stop. These products must be designed to outlive the process by which they are made, by as long as possible.

How would one organize such a production scheme on an industrial scale? Is it even possible? If it is not, then the only recourse is to have this done by garage, basement and backyard tinkerers, using plans shared over the internet. In fact, this seems to be what is happening, and it very well may be all that ever happens. If that is the case, then production volumes will be much lower than what can be attained with mass production techniques, leaving a huge unmet demand, and a far more precipitous drop in living standards than is really necessary. But let us imagine for a moment that we can do better. How would we go about organizing such an effort? Here are some thought experiments—projections, if you will—based on what I've observed over the years. I present three scenarios—not a complete list, I hope, but these are all the scenarios I can think of without straining my imagination. I hope that you can do better.

Image above: From "Home Made" a toy train by Aleksandr Chebotaryov for his son in 1996.

Company A

Suppose you have a company that sets out to make a widget. Let's call it Company A. Its founders are all engineers, of an uncompromising sort, and the widget they design and manufacture is of tremendous longevity, durability and overall quality. Taking full advantage of economies of scale, they design a single, universal model that uses the maximum possible number of interchangeable, off-the-shelf commodity components, optimize it for mass production, and stockpile a gigantic inventory, including all the custom spare parts that they feel would ever be needed. To make sure that their product is sufficiently idiot-proof, they even test it on selected members of their own families. The engineers concentrate on what they feel is important, neglecting questions of marketability and competitive pricing, and the result is that Company A's widget cost double of functionally comparable widgets sold by the competition.

When consumers refuse to pay so much more than they feel they have to, Company A's widget fails in the marketplace, and the company is liquidated. Its remaining stock of widgets is eventually sold at a large discount, while Company A's investors get almost nothing. Those who are lucky and clever enough to buy one of these widgets go on to use them for the rest of their lives, never needing to buy another one, because, being grossly overdesigned and overbuilt, they simply never fail or wear out. In spite of Company A's failure as a business, the reputations of the engineers do not suffer at all, because, after all, their product is a tremendous technical success. Furthermore, since the installed base of their widgets never goes down, the engineers remain in demand as consultants, called in whenever issues do arise. Some of them form a small company that maintains an inventory of spare parts, and uses it to recondition and service their widgets far into the future. Eventually, long after the names of Company A's competitors are all forgotten, its name enters the language as the generic term for the widget it once made.

Company B

Now suppose you have another company, Company B, which makes a similar sort of widget. Its founders are all MBAs who are mainly interested in things like growth strategies, market penetration and continuous profitability. They are superficially interested in the widget itself, as consumers or from a sales and marketing perspective. The internal workings of the widget are, to them, best left up to the engineers. They do hire some smart engineers to start with, but don't give them much of a voice in making strategic decisions, and manage them by doling out bonuses and promotions for things like new features, shorter time to market, and lower production costs. They see to it that the widget they make is competitively priced, fashionably designed, and quickly obsolescent, so that consumers are ready to pay again and again just to get the latest features and designs. Durability and longevity are not a concern, since one or two years of semi-reliable service is all that's needed for Company B to come up with a new, improved version that consumers can be persuaded to buy given a sufficiently generous trade-in offer.

They work to boost revenue by offering an extended warranty or a service plan (made necessary by frequent breakdowns), charging for premium customer service (made necessary by their normal customer service, which consists of a robotic phone maze backed by a few trainees in India who just read aloud from Company B's public web site in a listless, stuttering monotone) and offering numerous enhancements and upgrades (made necessary by annoyances or missing functions within the base product). They also build a profit center out of selling spare parts. They see to it that their product does not contain any commodity parts, and that no parts are interchangeable between model years, so that every replacement part has to be purchased through a dealer. Company B does quite well, becoming profitable, doubling in size several times, and gains a commanding market share.

But then the troubles begin. First, given the short replacement cycle of its widget, it becomes harder and harder for Company B to contain costs while continuing to increase production. Costs of key inputs, such as certain metals, plastics, energy to run the plants, and shipping and distribution costs, all start going up, making their widgets more expensive to produce. At the same time, it becomes increasingly difficult to pass these higher costs on to the consumers. Concerted efforts at cost containment, championed by senior management, burn up more money than they find in savings. Second, turnover among the engineering staff starts to creep up, and after a while employee retention becomes a major problem. An effort is made to boost recruitment, but paradoxically this only increases the turnover rate, until the average tenure of an engineer is shorter than the time it takes to learn the product.

As development timelines slip and defect rates increase, management throws money at the problem by hiring high-priced consultants and engineering methodology snake oil salesmen, all to no avail. Lastly, although Company B manages to hold on to its market share, the overall size of the market starts to shrink as consumers run out of money and curtail their purchases, holding on to their outdated widgets until they fail, then learning to live without them. Eventually Company B is acquired by a foreign company, which crates up and ships off the few pieces of the operation it finds useful and auctions off the rest. As Company B's customers try to eke out a bit more life out of their half-broken widgets, the average resale price of Company A's widget soars well above its initial list price, and its proud owners go around looking insufferably smug.

Company C

Company C is not really a company but a consortium organized by a group of activists who correctly perceive the great need for this widget and decide to tackle the issue head-on through tireless community organizing. Their initial concept includes plans for the widget to carry a "100% Sustainable" label. A group of retired community college professors takes several months to define the technology selection criteria that would allow the project to meet the 100% sustainability requirement. In the end, they decide that the widget could be made out of hand-worked clay baked in a solar oven, but only if the oven itself is exempted from the 100% sustainability requirement. It could also be hand-woven out of wicker and bamboo, provided that these were subsequently composted and the compost returned to the soil where the wicker and bamboo were grown. However, the widget can't be made to work without the use of Nylon, Vinyl, Neoprene, epoxies and other fossil fuel-based synthetics, nor can it operate without components made with mined, increasingly scarce elements such as tantalum, gallium and lithium.

The organizers then move to drop the "100% sustainable" requirement and to shift their focus to "Serving community at every level." Production of the widget is to include hands-on job training programs at community colleges and vocational training centers, assembly tasks would be done by groups of mentally and/or physically challenged individuals, while testing, kitting-out and packing would be performed by religious groups (in conservative states) and groups of people with alternative sexual orientations (in liberal ones). From the outset, the consortium is plagued by scandal. The "Made with Pride in the USA" decals turn out to be made in China. The Visual Installation Guide is never printed in Braille. Worst of all, due to communication difficulties caused by static and noise on the line during conference calls, the lesbians (who were to lovingly pack completed widgets in wicker baskets hand-woven by Haitian orphans and filled with organically grown straw) turn out to be not lesbians at all, but eager out-of-work Thespians (of both genders, and barely half of them gay) and Fezbians (perfectly conventional males with convincing falsettos united by their predilection for wearing a fez). The consortium collapses in acrimony and mutual recriminations without shipping a single completed widget. Out of sheer frustration, one of the organizers, laboring alone, succeeds in assembling a single working widget, and donates it to the Smithsonian.

Conclusion

Based on the foregoing, it would appear that the choice is between failing at something and failing at everything. Company A makes excellent widgets but fails to pay back its investors. Company B makes money but its widgets quickly become useless trash. Company C entertains us with its feckless shenanigans but fails to produce any widgets. I really do hope that I am missing something. Is there a Company D out there? If so, please tell me, because I would really like to know.

.

Image above: From "Home Made" a toy train by Aleksandr Chebotaryov for his son in 1996.

Company A

Suppose you have a company that sets out to make a widget. Let's call it Company A. Its founders are all engineers, of an uncompromising sort, and the widget they design and manufacture is of tremendous longevity, durability and overall quality. Taking full advantage of economies of scale, they design a single, universal model that uses the maximum possible number of interchangeable, off-the-shelf commodity components, optimize it for mass production, and stockpile a gigantic inventory, including all the custom spare parts that they feel would ever be needed. To make sure that their product is sufficiently idiot-proof, they even test it on selected members of their own families. The engineers concentrate on what they feel is important, neglecting questions of marketability and competitive pricing, and the result is that Company A's widget cost double of functionally comparable widgets sold by the competition.

When consumers refuse to pay so much more than they feel they have to, Company A's widget fails in the marketplace, and the company is liquidated. Its remaining stock of widgets is eventually sold at a large discount, while Company A's investors get almost nothing. Those who are lucky and clever enough to buy one of these widgets go on to use them for the rest of their lives, never needing to buy another one, because, being grossly overdesigned and overbuilt, they simply never fail or wear out. In spite of Company A's failure as a business, the reputations of the engineers do not suffer at all, because, after all, their product is a tremendous technical success. Furthermore, since the installed base of their widgets never goes down, the engineers remain in demand as consultants, called in whenever issues do arise. Some of them form a small company that maintains an inventory of spare parts, and uses it to recondition and service their widgets far into the future. Eventually, long after the names of Company A's competitors are all forgotten, its name enters the language as the generic term for the widget it once made.

Company B

Now suppose you have another company, Company B, which makes a similar sort of widget. Its founders are all MBAs who are mainly interested in things like growth strategies, market penetration and continuous profitability. They are superficially interested in the widget itself, as consumers or from a sales and marketing perspective. The internal workings of the widget are, to them, best left up to the engineers. They do hire some smart engineers to start with, but don't give them much of a voice in making strategic decisions, and manage them by doling out bonuses and promotions for things like new features, shorter time to market, and lower production costs. They see to it that the widget they make is competitively priced, fashionably designed, and quickly obsolescent, so that consumers are ready to pay again and again just to get the latest features and designs. Durability and longevity are not a concern, since one or two years of semi-reliable service is all that's needed for Company B to come up with a new, improved version that consumers can be persuaded to buy given a sufficiently generous trade-in offer.

They work to boost revenue by offering an extended warranty or a service plan (made necessary by frequent breakdowns), charging for premium customer service (made necessary by their normal customer service, which consists of a robotic phone maze backed by a few trainees in India who just read aloud from Company B's public web site in a listless, stuttering monotone) and offering numerous enhancements and upgrades (made necessary by annoyances or missing functions within the base product). They also build a profit center out of selling spare parts. They see to it that their product does not contain any commodity parts, and that no parts are interchangeable between model years, so that every replacement part has to be purchased through a dealer. Company B does quite well, becoming profitable, doubling in size several times, and gains a commanding market share.

But then the troubles begin. First, given the short replacement cycle of its widget, it becomes harder and harder for Company B to contain costs while continuing to increase production. Costs of key inputs, such as certain metals, plastics, energy to run the plants, and shipping and distribution costs, all start going up, making their widgets more expensive to produce. At the same time, it becomes increasingly difficult to pass these higher costs on to the consumers. Concerted efforts at cost containment, championed by senior management, burn up more money than they find in savings. Second, turnover among the engineering staff starts to creep up, and after a while employee retention becomes a major problem. An effort is made to boost recruitment, but paradoxically this only increases the turnover rate, until the average tenure of an engineer is shorter than the time it takes to learn the product.

As development timelines slip and defect rates increase, management throws money at the problem by hiring high-priced consultants and engineering methodology snake oil salesmen, all to no avail. Lastly, although Company B manages to hold on to its market share, the overall size of the market starts to shrink as consumers run out of money and curtail their purchases, holding on to their outdated widgets until they fail, then learning to live without them. Eventually Company B is acquired by a foreign company, which crates up and ships off the few pieces of the operation it finds useful and auctions off the rest. As Company B's customers try to eke out a bit more life out of their half-broken widgets, the average resale price of Company A's widget soars well above its initial list price, and its proud owners go around looking insufferably smug.

Company C

Company C is not really a company but a consortium organized by a group of activists who correctly perceive the great need for this widget and decide to tackle the issue head-on through tireless community organizing. Their initial concept includes plans for the widget to carry a "100% Sustainable" label. A group of retired community college professors takes several months to define the technology selection criteria that would allow the project to meet the 100% sustainability requirement. In the end, they decide that the widget could be made out of hand-worked clay baked in a solar oven, but only if the oven itself is exempted from the 100% sustainability requirement. It could also be hand-woven out of wicker and bamboo, provided that these were subsequently composted and the compost returned to the soil where the wicker and bamboo were grown. However, the widget can't be made to work without the use of Nylon, Vinyl, Neoprene, epoxies and other fossil fuel-based synthetics, nor can it operate without components made with mined, increasingly scarce elements such as tantalum, gallium and lithium.

The organizers then move to drop the "100% sustainable" requirement and to shift their focus to "Serving community at every level." Production of the widget is to include hands-on job training programs at community colleges and vocational training centers, assembly tasks would be done by groups of mentally and/or physically challenged individuals, while testing, kitting-out and packing would be performed by religious groups (in conservative states) and groups of people with alternative sexual orientations (in liberal ones). From the outset, the consortium is plagued by scandal. The "Made with Pride in the USA" decals turn out to be made in China. The Visual Installation Guide is never printed in Braille. Worst of all, due to communication difficulties caused by static and noise on the line during conference calls, the lesbians (who were to lovingly pack completed widgets in wicker baskets hand-woven by Haitian orphans and filled with organically grown straw) turn out to be not lesbians at all, but eager out-of-work Thespians (of both genders, and barely half of them gay) and Fezbians (perfectly conventional males with convincing falsettos united by their predilection for wearing a fez). The consortium collapses in acrimony and mutual recriminations without shipping a single completed widget. Out of sheer frustration, one of the organizers, laboring alone, succeeds in assembling a single working widget, and donates it to the Smithsonian.

Conclusion

Based on the foregoing, it would appear that the choice is between failing at something and failing at everything. Company A makes excellent widgets but fails to pay back its investors. Company B makes money but its widgets quickly become useless trash. Company C entertains us with its feckless shenanigans but fails to produce any widgets. I really do hope that I am missing something. Is there a Company D out there? If so, please tell me, because I would really like to know.

.

No comments :

Post a Comment