SUBHEAD: New battery technologies are pushing ahead, quietly and without much fanfare.

ByAmeria Urray on 21 March 2017 for Grist Magazine -

(http://grist.org/climate-energy/the-future-will-be-battery-powered/)

Image above: Illustration of a common 1.5volt appliance battery. From original article.

The battery might be the least sexy piece of technology ever invented. The lack of glamour is especially conspicuous on the lower floors of MIT’s materials science department, where one lab devoted to building and testing the next world-changing energy storage device could easily be mistaken for a storage closet.

At the back of the cramped room, Donald Sadoway, a silver-haired electrochemist in a trim black-striped suit and expensive-looking shoes, rummages through a plastic tub of parts like a kid in search of a particular Lego. He sets a pair of objects on the table, each about the size and shape of a can of soup with all the inherent drama of a paperweight.

No wonder it’s so hard to get anyone excited about batteries. But these paperweights — er, battery cells — could be the technology that revolutionizes our energy system.

Because batteries aren’t just boring. Frankly, they kinda suck. At best, the batteries that power our daily lives are merely invisible — easily drained reservoirs of power packed into smartphones and computers and cars.

At worst, they are expensive, heavy, combustible, complicated to dispose of properly, and prone to dying in the cold or oozing corrosive fluid. Even as the devices they power become slimmer and smarter, batteries are still waiting for their next upgrade.

Computer processors famously double their capacity every two years; batteries may scrounge only a few percentage points of improvement in the same amount of time.

Nevertheless, the future will be battery-powered. It has to be. From electric cars to industrial-scale solar farms, batteries are the key to a cleaner, more efficient energy system — and the sooner we get there, the sooner we can stop contributing to potentially catastrophic climate change.

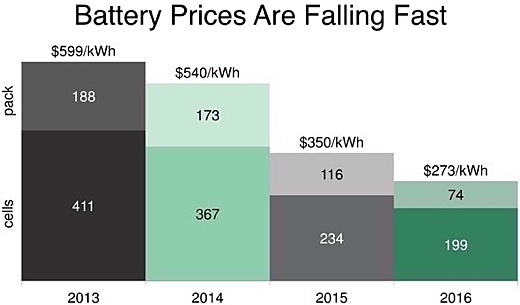

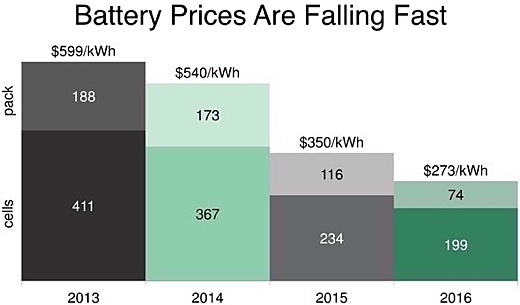

But the batteries we’ve got — mostly lithium-ion — aren’t good enough. There’s been some progress: The cost of storing energy has fallen by half over the last five years, and big companies are increasingly making marquee investments in the technology, like Tesla’s ‘gigafactory.’

Image above: Chart of reduction in cost of batteries (including those for electric cars. From original article and (https://www.bloomberg.com/news/articles/2017-01-30/tesla-s-battery-revolution-just-reached-critical-mass).

But in terms of wholesale economic transformation, lithium-ion batteries remain too expensive. They are powerful in our devices, but when you scale them up they are liable to overheat and even, occasionally, explode.

Perhaps the biggest problem with lithium-ion batteries is that they wear out. Think of your phone battery after it’s spent a few years draining to 1 percent then charging back up to 100. That kind of deep discharge and recharge takes a physical toll and damages a battery’s performance over time.

So we’re overdue for a brand new battery, and researchers around the world are racing to give us one, with competing approaches and technologies vying for top spot.

Some of their ideas are like nothing we’ve ever plugged into the grid — still not sexy, exactly, but definitely surprising. Liquid batteries. Batteries of molten metal that run as hot as a car engine. Batteries whose secret ingredient is saltwater.

It’s all part of a brand new space race — if less flashy than, you know, outer space.

“The biggest problem is still cost,” says Eric Rohlfing, deputy director of technology for ARPA-E, a division of the Department of Energy that identifies and funds cutting-edge research and development.

A 2012 study in Nature found that the average American would only be willing to pay about $13 more each month to ensure that the entire U.S. electrical supply ran on renewables. So batteries can’t add much to electrical bills.

For utilities, that means providing grid-level energy storage that would cost them less than $100 per kilowatt hour. Since it was established by President Obama in 2009, ARPA-E has put $85 million toward developing new batteries that can meet that goal.

“People called us crazy,” says Rohlfing. That number was absurdly low for an industry that hadn’t yet seen the near side of $700 per kilowatt hours when they started, according to one study of electric vehicle batteries published in Nature.

Now, though still unattained, $100 per kWh is the standard target across the industry, Rohlfing says. Get below that, it seems, and you can not only compete — you can win.

And here’s what a better battery stands to win: a cleaner, more reliable power system, which doesn’t rely on fossil fuels and is more robust to boot.

Every time you flip a light switch, you tap into a gigantic invisible web, the electrical grid. Somewhere, at the other end of the high-voltage transmission lines carrying power to your house, there’s a power plant (likely burning coal or, increasingly, natural gas) churning out the electricity that you and everyone else are draining at that moment.

The amount of power in our grid at any one time is carefully maintained — too much or too little and things start to break. Grid operators make careful observations and predictions to determine how much electricity power plants should produce, minute by minute, hour by hour.

But sometimes they’re wrong, and a plant has to power up in a hurry to make up the difference.

Lucky for us, it’s a big, interconnected system, so we rarely notice changes in the quality or quantity of electricity. Imagine the difference between stepping into a bucket of water versus stepping into the ocean. In a small system, any change in the balance between supply and demand is obvious — the bucket overflows.

But because the grid is so big — ocean-like — fluctuations are usually imperceptible. Only when something goes very wrong do we notice, because the lights go out.

Renewable energy is less obedient than a coal- or gas-fired power plant — you can’t just fire up a solar farm if demand spikes suddenly. Solar power peaks during the day, varies as clouds move across the sun, and disappears at night, while wind power is even less predictable.

Too much of that kind of intermittency on the grid could make it more difficult to balance supply and demand, which could lead to more blackouts.

Storing energy is a safety valve. If you could dump extra energy somewhere, then draw from it when supply gets low again, you can power a whole lot more stuff with renewable energy, even when the sun isn’t shining and the wind isn’t blowing.

What’s more, the grid itself becomes more stable and efficient, as batteries would allow communities and regions to manage their own power supply.

Our aging and overtaxed power infrastructure would go a lot further. Instead of installing new transmission lines in places where existing lines are near capacity, you could draw power during off-peak times and stash it in batteries until you need it.

Just like that, the bucket can behave a lot more like the ocean. That would mean — at least in theory — more distributed power generation and storage, more renewables, and less reliance on giant fossil-fueled power plants.

So that’s why this battery thing is kind of A Big Deal.

Those canisters he showed me were early prototypes of cells for a “liquid metal battery” he started researching a decade ago.

“I started working on batteries just because I was crazy about cars,” Sadoway tells me. (His desktop background is a 1961 Studebaker Avanti he sold a few years ago. He keeps the picture around the way one would memorialize a family pet.)

In 1995, he took a test drive in an early Ford electric vehicle and fell in love. “I realized the only reason we don’t have electric cars is because we don’t have batteries.”

So Sadoway started thinking. He had some experience with the process of refining aluminum, and he wondered if that could be a model for a new, unorthodox kind of battery. Aluminum smelting is a dirt-cheap, energy-intensive process by which purified metal is boiled out of ore.

But if that one-way process could be doubled up and looped back on itself, maybe the huge amount of energy fed into the molten metal could be stored there.

In some ways, that’s insane — the molten battery would have to run around of 880 degrees F, only slightly cooler than the combustion chamber of a car engine.

But it’s also a bizarrely simple concept, at least to an electrochemist. It turns out assembling a cell of a liquid metal battery cell is as easy as dropping a plug of metal, made up of two alloys of different densities, into a vessel and pouring some salt on top.

When the cell is powered up, the two metals melt and divide into two layers automatically, like salad oil floating on vinegar. The molten salt forms a layer between them, conducting electrons back and forth.

But even with a promising start, developing a new battery is a glacially slow process, Sadoway says. Early funding from ARPA-E and the French oil giant Total helped him get the idea off the ground, but sustaining research for the years needed to build any brand new technology is expensive.

Venture capitalists are shy about drawn-out engineering projects when there are so many software startups promising fast profits.

“In any capital-intensive industry, industry will stand in the way of innovation,” Sadoway says. Existing battery companies have too much invested in the status quo to be much help, he says. Lithium-ion came from outside the established battery industry of its time, he points out; the next battery will have to do the same.

The molten metal battery has long since moved out of the basement lab. In 2010, Sadoway started the battery company Ambri with several of his former students, then moved HQ into a manufacturing facility 30 miles west of Cambridge to the town of Marlborough.

Now, Ambri employs about 40 people and is busy building prototype battery packs out of hundreds of the molten metal cells.

Sadoway says Ambri is less than a year away from deploying its first commercial models. All signs have been hopeful so far, he says. At the manufacturing facility, some test cells have been up and running for almost four years without showing any signs of wear and tear.

Getting the assembled battery packs, each consisting of 432 individual cells, to work was trickier. But after ironing out some pesky issues with the heat seals, the battery packs can reach a self-sustaining operating temperature, hot enough to charge and discharge without any extra energy input.

Now Ambri is in the middle of raising another round of funding, enough to reach market-ready production mode.

On my way out the door, I say that, for all the difficulty and delay, it seems like this battery could really be close. “I hope so,” Sadoway says, looking almost wistful. “Maybe this is it. I’d like to see that.”

Like Sadoway’s project, many of these untested technologies are funded initially by grants from ARPA-E. “These are very early stage, high-risk technologies,” says Rohlfing, the agency’s deputy director. “We take a lot of shots on goal.”

One especially promising contender in the better battery battle is the Pittsburgh-based company Aquion, whose founder, Carnegie Mellon professor Jay Whitacre, set out in 2008 to design the cheapest, most reliable battery you could make.

The result is something colloquially called a “saltwater battery.” It looks, more or less, like a Rubbermaid bin full of seawater. All of the materials in the Aquion batteries are abundant and easily obtained elements, from salt to stainless steel to cotton. What’s more, none of those materials carry the risks of a lithium-ion battery.

“Our chemistry is very simple,” says Matt Maroon, Aquion’s vice president of product management. “There’s nothing in our battery that is flammable, toxic, or caustic.”

Image above: Battery storage array. From original article.

It’s also stupidly easy to assemble. “Our main piece of manufacturing assembly equipment comes out of the food packaging industry,” Maroon says. “It’s a simple pick-and-place robot that you’d find at Nabisco, putting crackers inside of blister packs.”

Aquion batteries have been on the market for nearly three years, installed in both homes and utility-scale facilities.

Overall, Aquion has 35 megawatt hours of storage deployed around the world in 250 different installations. One in Hawaii has been up and running for two years; last year, the battery-plus-solar system powered several buildings for six months without ever falling back on a diesel generator.

“We need to get more of these things out into the field,” says Rohlfing. “Right now, if I’m a utility or a grid operator and I want to buy storage, I want to buy something that comes with a 20-year warranty. The technologies we’re talking about aren’t at that stage yet.”

But they’re getting close. Another ARPA-E-funded project, Energy Storage Systems, or ESS, announced last November that it would install one of its iron-flow batteries as part of an Army Corps of Engineers microgrid experiment on a military base in Missouri.

ESS has also installed batteries to help power an off-grid organic winery in Napa Valley — for that matter, so has Aquion. As more and more of these one-off experiments prove successful — and more of these new kinds of batteries prove their worth — the possibility of a battery-powered energy system comes a little closer.

But will batteries ever be, well, cool? That’s a harder question. Aquion’s Matt Maroon has been working in the field since 2002, soon after he left college. At conferences, Maroon was often the youngest person in the room by 30 years. He was sure he wouldn’t be “a battery guy” for his whole career.

Fifteen years later, he’s still a battery guy — but he’s no longer the youngest person in the room.

More students are starting to get involved with batteries, and people are starting to take notice. “It’s still not as a cool as working at Apple,” he says. “But I think people recognize its importance and that kind of makes it cool.”

“Or I hope so,” he laughs. “I’ve got a 9-year-old daughter. So I’d like to work on something that she thinks is cool someday. That’s my ultimate goal.”

ByAmeria Urray on 21 March 2017 for Grist Magazine -

(http://grist.org/climate-energy/the-future-will-be-battery-powered/)

Image above: Illustration of a common 1.5volt appliance battery. From original article.

The battery might be the least sexy piece of technology ever invented. The lack of glamour is especially conspicuous on the lower floors of MIT’s materials science department, where one lab devoted to building and testing the next world-changing energy storage device could easily be mistaken for a storage closet.

At the back of the cramped room, Donald Sadoway, a silver-haired electrochemist in a trim black-striped suit and expensive-looking shoes, rummages through a plastic tub of parts like a kid in search of a particular Lego. He sets a pair of objects on the table, each about the size and shape of a can of soup with all the inherent drama of a paperweight.

No wonder it’s so hard to get anyone excited about batteries. But these paperweights — er, battery cells — could be the technology that revolutionizes our energy system.

Because batteries aren’t just boring. Frankly, they kinda suck. At best, the batteries that power our daily lives are merely invisible — easily drained reservoirs of power packed into smartphones and computers and cars.

At worst, they are expensive, heavy, combustible, complicated to dispose of properly, and prone to dying in the cold or oozing corrosive fluid. Even as the devices they power become slimmer and smarter, batteries are still waiting for their next upgrade.

Computer processors famously double their capacity every two years; batteries may scrounge only a few percentage points of improvement in the same amount of time.

Nevertheless, the future will be battery-powered. It has to be. From electric cars to industrial-scale solar farms, batteries are the key to a cleaner, more efficient energy system — and the sooner we get there, the sooner we can stop contributing to potentially catastrophic climate change.

But the batteries we’ve got — mostly lithium-ion — aren’t good enough. There’s been some progress: The cost of storing energy has fallen by half over the last five years, and big companies are increasingly making marquee investments in the technology, like Tesla’s ‘gigafactory.’

Image above: Chart of reduction in cost of batteries (including those for electric cars. From original article and (https://www.bloomberg.com/news/articles/2017-01-30/tesla-s-battery-revolution-just-reached-critical-mass).

But in terms of wholesale economic transformation, lithium-ion batteries remain too expensive. They are powerful in our devices, but when you scale them up they are liable to overheat and even, occasionally, explode.

Perhaps the biggest problem with lithium-ion batteries is that they wear out. Think of your phone battery after it’s spent a few years draining to 1 percent then charging back up to 100. That kind of deep discharge and recharge takes a physical toll and damages a battery’s performance over time.

So we’re overdue for a brand new battery, and researchers around the world are racing to give us one, with competing approaches and technologies vying for top spot.

Some of their ideas are like nothing we’ve ever plugged into the grid — still not sexy, exactly, but definitely surprising. Liquid batteries. Batteries of molten metal that run as hot as a car engine. Batteries whose secret ingredient is saltwater.

It’s all part of a brand new space race — if less flashy than, you know, outer space.

Just add batteries

There are a few things you want in a good battery, but two are essential: It needs to be reliable, and it needs to be cheap.“The biggest problem is still cost,” says Eric Rohlfing, deputy director of technology for ARPA-E, a division of the Department of Energy that identifies and funds cutting-edge research and development.

A 2012 study in Nature found that the average American would only be willing to pay about $13 more each month to ensure that the entire U.S. electrical supply ran on renewables. So batteries can’t add much to electrical bills.

For utilities, that means providing grid-level energy storage that would cost them less than $100 per kilowatt hour. Since it was established by President Obama in 2009, ARPA-E has put $85 million toward developing new batteries that can meet that goal.

“People called us crazy,” says Rohlfing. That number was absurdly low for an industry that hadn’t yet seen the near side of $700 per kilowatt hours when they started, according to one study of electric vehicle batteries published in Nature.

Now, though still unattained, $100 per kWh is the standard target across the industry, Rohlfing says. Get below that, it seems, and you can not only compete — you can win.

And here’s what a better battery stands to win: a cleaner, more reliable power system, which doesn’t rely on fossil fuels and is more robust to boot.

Every time you flip a light switch, you tap into a gigantic invisible web, the electrical grid. Somewhere, at the other end of the high-voltage transmission lines carrying power to your house, there’s a power plant (likely burning coal or, increasingly, natural gas) churning out the electricity that you and everyone else are draining at that moment.

The amount of power in our grid at any one time is carefully maintained — too much or too little and things start to break. Grid operators make careful observations and predictions to determine how much electricity power plants should produce, minute by minute, hour by hour.

But sometimes they’re wrong, and a plant has to power up in a hurry to make up the difference.

Lucky for us, it’s a big, interconnected system, so we rarely notice changes in the quality or quantity of electricity. Imagine the difference between stepping into a bucket of water versus stepping into the ocean. In a small system, any change in the balance between supply and demand is obvious — the bucket overflows.

But because the grid is so big — ocean-like — fluctuations are usually imperceptible. Only when something goes very wrong do we notice, because the lights go out.

Renewable energy is less obedient than a coal- or gas-fired power plant — you can’t just fire up a solar farm if demand spikes suddenly. Solar power peaks during the day, varies as clouds move across the sun, and disappears at night, while wind power is even less predictable.

Too much of that kind of intermittency on the grid could make it more difficult to balance supply and demand, which could lead to more blackouts.

Storing energy is a safety valve. If you could dump extra energy somewhere, then draw from it when supply gets low again, you can power a whole lot more stuff with renewable energy, even when the sun isn’t shining and the wind isn’t blowing.

What’s more, the grid itself becomes more stable and efficient, as batteries would allow communities and regions to manage their own power supply.

Our aging and overtaxed power infrastructure would go a lot further. Instead of installing new transmission lines in places where existing lines are near capacity, you could draw power during off-peak times and stash it in batteries until you need it.

Just like that, the bucket can behave a lot more like the ocean. That would mean — at least in theory — more distributed power generation and storage, more renewables, and less reliance on giant fossil-fueled power plants.

So that’s why this battery thing is kind of A Big Deal.

Heating up

“A battery will do for the electricity supply chain what refrigeration did to our food supply chain,” Sadoway says from his office in MIT, a good deal more spacious than the battery lab.Those canisters he showed me were early prototypes of cells for a “liquid metal battery” he started researching a decade ago.

“I started working on batteries just because I was crazy about cars,” Sadoway tells me. (His desktop background is a 1961 Studebaker Avanti he sold a few years ago. He keeps the picture around the way one would memorialize a family pet.)

In 1995, he took a test drive in an early Ford electric vehicle and fell in love. “I realized the only reason we don’t have electric cars is because we don’t have batteries.”

So Sadoway started thinking. He had some experience with the process of refining aluminum, and he wondered if that could be a model for a new, unorthodox kind of battery. Aluminum smelting is a dirt-cheap, energy-intensive process by which purified metal is boiled out of ore.

But if that one-way process could be doubled up and looped back on itself, maybe the huge amount of energy fed into the molten metal could be stored there.

In some ways, that’s insane — the molten battery would have to run around of 880 degrees F, only slightly cooler than the combustion chamber of a car engine.

But it’s also a bizarrely simple concept, at least to an electrochemist. It turns out assembling a cell of a liquid metal battery cell is as easy as dropping a plug of metal, made up of two alloys of different densities, into a vessel and pouring some salt on top.

When the cell is powered up, the two metals melt and divide into two layers automatically, like salad oil floating on vinegar. The molten salt forms a layer between them, conducting electrons back and forth.

But even with a promising start, developing a new battery is a glacially slow process, Sadoway says. Early funding from ARPA-E and the French oil giant Total helped him get the idea off the ground, but sustaining research for the years needed to build any brand new technology is expensive.

Venture capitalists are shy about drawn-out engineering projects when there are so many software startups promising fast profits.

“In any capital-intensive industry, industry will stand in the way of innovation,” Sadoway says. Existing battery companies have too much invested in the status quo to be much help, he says. Lithium-ion came from outside the established battery industry of its time, he points out; the next battery will have to do the same.

The molten metal battery has long since moved out of the basement lab. In 2010, Sadoway started the battery company Ambri with several of his former students, then moved HQ into a manufacturing facility 30 miles west of Cambridge to the town of Marlborough.

Now, Ambri employs about 40 people and is busy building prototype battery packs out of hundreds of the molten metal cells.

Sadoway says Ambri is less than a year away from deploying its first commercial models. All signs have been hopeful so far, he says. At the manufacturing facility, some test cells have been up and running for almost four years without showing any signs of wear and tear.

Getting the assembled battery packs, each consisting of 432 individual cells, to work was trickier. But after ironing out some pesky issues with the heat seals, the battery packs can reach a self-sustaining operating temperature, hot enough to charge and discharge without any extra energy input.

Now Ambri is in the middle of raising another round of funding, enough to reach market-ready production mode.

On my way out the door, I say that, for all the difficulty and delay, it seems like this battery could really be close. “I hope so,” Sadoway says, looking almost wistful. “Maybe this is it. I’d like to see that.”

A crowded field

The molten metal battery isn’t the only moonshot battery. It’s not even the obvious front-runner. Other technologies are pushing ahead, quietly and without fanfare, from “iron flow batteries” to zinc- and lithium-air varieties.Like Sadoway’s project, many of these untested technologies are funded initially by grants from ARPA-E. “These are very early stage, high-risk technologies,” says Rohlfing, the agency’s deputy director. “We take a lot of shots on goal.”

One especially promising contender in the better battery battle is the Pittsburgh-based company Aquion, whose founder, Carnegie Mellon professor Jay Whitacre, set out in 2008 to design the cheapest, most reliable battery you could make.

The result is something colloquially called a “saltwater battery.” It looks, more or less, like a Rubbermaid bin full of seawater. All of the materials in the Aquion batteries are abundant and easily obtained elements, from salt to stainless steel to cotton. What’s more, none of those materials carry the risks of a lithium-ion battery.

“Our chemistry is very simple,” says Matt Maroon, Aquion’s vice president of product management. “There’s nothing in our battery that is flammable, toxic, or caustic.”

Image above: Battery storage array. From original article.

It’s also stupidly easy to assemble. “Our main piece of manufacturing assembly equipment comes out of the food packaging industry,” Maroon says. “It’s a simple pick-and-place robot that you’d find at Nabisco, putting crackers inside of blister packs.”

Aquion batteries have been on the market for nearly three years, installed in both homes and utility-scale facilities.

Overall, Aquion has 35 megawatt hours of storage deployed around the world in 250 different installations. One in Hawaii has been up and running for two years; last year, the battery-plus-solar system powered several buildings for six months without ever falling back on a diesel generator.

“We need to get more of these things out into the field,” says Rohlfing. “Right now, if I’m a utility or a grid operator and I want to buy storage, I want to buy something that comes with a 20-year warranty. The technologies we’re talking about aren’t at that stage yet.”

But they’re getting close. Another ARPA-E-funded project, Energy Storage Systems, or ESS, announced last November that it would install one of its iron-flow batteries as part of an Army Corps of Engineers microgrid experiment on a military base in Missouri.

ESS has also installed batteries to help power an off-grid organic winery in Napa Valley — for that matter, so has Aquion. As more and more of these one-off experiments prove successful — and more of these new kinds of batteries prove their worth — the possibility of a battery-powered energy system comes a little closer.

But will batteries ever be, well, cool? That’s a harder question. Aquion’s Matt Maroon has been working in the field since 2002, soon after he left college. At conferences, Maroon was often the youngest person in the room by 30 years. He was sure he wouldn’t be “a battery guy” for his whole career.

Fifteen years later, he’s still a battery guy — but he’s no longer the youngest person in the room.

More students are starting to get involved with batteries, and people are starting to take notice. “It’s still not as a cool as working at Apple,” he says. “But I think people recognize its importance and that kind of makes it cool.”

“Or I hope so,” he laughs. “I’ve got a 9-year-old daughter. So I’d like to work on something that she thinks is cool someday. That’s my ultimate goal.”

No comments :

Post a Comment